Thanks to community member Chris Gregg for writing this article!

Translating Intakes

Before starting this process, I spoke with other enthusiasts about their experience modifying automotive intakes. I wanted to know how they decided which intake to run, what information they wish would have been available from the start, and are there things they still find confusing. Given the inherent differences between engines (number of cylinders, engine displacement, single vs double overhead cams, etc) and the application of more complicated intake designs (single throttle body vs dual throttle bodies), it’s difficult to address everything someone might need to know about intakes in such a brief article. Therefore, we will be speaking generally on how intakes work, establishing the “rules of thumb,” so you can have an accurate understanding and ultimately make an informed decision for your particular application.

At a glance, factory intake systems still resemble early versions when fuel injection was at its infancy. You have a box that filters the air, an intake tube creating a pathway for air to travel between the filter box and engine, a throttle body controlling air entering the upper intake plenum, the upper intake distributes air into individual runners leading through the lower intake manifold and subsequently enters the head(s), where the air is finally directed into each cylinder by way of the intake valves. The role each component plays in affecting airflow into the engine is indeed complex. Adding to that complexity, modern engines incorporate systems like variable length intakes, swirl valves, and air straighteners that go unseen by most enthusiasts. How intake modifications subsequently affect engine performance is often based on the notion factory designs are restrictive and therefore diminish power and performance. Although this is often true for older vehicles (1980’s and 90’s), modern intake system designs have become progressively better designed and tend to flow air beyond what the engine needs under normal daily use. So then why does replacing the intake tube and filter on newer vehicles result in driver observations of improved throttle response and acceleration? Intake design is a balancing act between multiple factors for manufactures. A few examples being production cost, fuel economy, durability/longevity, and how changes impact the engine’s power-band. Just because a system flows well does not mean it performs equally across the power-band or that it is without limitations. To understand why a modification results in an improvement, we really need to know where the factory system least efficient?

As we begin talking about efficiency, it’s necessary to understand the relevance of atmospheric pressure, which is estimated at 14.7 pounds per square inch at sea level. Of course, atmospheric pressure will differ based on various factors such as elevation above sea level (less than 14.7) or below sea level (greater than 14.7 pounds per square inch). During a cylinder’s intake stroke as the piston travels down, air pressure is decreased inside the cylinder. The speed at which this occurs creates a sudden pressure difference between the low pressure at the cylinder compared to the higher atmospheric pressure outside of the intake system, resulting in air being drawn into the cylinder. Because engine cylinders access air through the intake system, they are not directly open to the atmosphere and subsequently will not see full atmospheric pressure – meaning a decrease in pressure at the cylinder occurs. The efficiency of the intake system ultimately determines how much atmospheric pressure is lost at the cylinder. The extent that an intake system either decreases pressure (bad for efficiency and power) or increases pressure (good for efficiency and power) is referred to as volumetric efficiency. Any part of an intake system that restricts airflow (slows it down) is considered a reduction to the intake’s volumetric efficiency. By identifying barriers and making changes to improve the intake system’s volumetric efficiency (achieving pressures closer to 14.7 pounds per square inch), we will subsequently improve engine performance because we have decreased the amount of pressure loss through the intake. To determine what causes intake restrictions/decreased pressure, let’s get a little more in-depth about behind-the-scenes functionality of factory intakes.

The starting point for air entering the system is the intake air box, which is at the furthest point from the engine. The primary purpose of the intake box is to house the air filter (more on that a little later). Depending on design, these boxes may draw air from outside the engine bay via a short tube running into the fender or location in front of the radiator/behind the grill. Intakes that draw air from outside the engine bay are referred to as Cold Air Intakes (CAI). In other vehicles the intake may pull air from the engine bay; possibly drawing air from behind the headlight, so that while the vehicle is stopped warmer air is collected. Once moving, the cooler outside air comes in around the headlight and grill making this intake design what is referred to as a Warm Air Intake (WAI). You will often see people refer to any intake that draws air from inside the engine bay as a Hot Air Intake (HAI) because air temperatures under the hood are naturally hotter than the air outside the vehicle.

It is important to understand where an intake system draws air in. Simply, warmer air reduces the power output of the engine while cooler air will increase power output. This is due to the fact cooler air has increased density; allowing a greater volume of air molecules to be packed into the same space. The benefit of cooler air is factored to be one horsepower for every ten degrees of change. Naturally this works both ways: consumption of 10* warmer air will result in one horse power loss and 10* cooler air will result in one horse power increase. That doesn’t sound like a whole lot, but when you figure air inside the engine bay can easily be 40* (or more) hotter than the air outside of the vehicle, you can see how temperature alone can result in a change of four horse power. For this reason, it is important to ensure the intake you choose is drawing air from the coolest source possible. Considering your typical daily routine, how much time do you spend sitting in slow moving traffic, higher speeds on the interstate, or off-road at low speeds and higher rpms/greater engine load? These are necessary questions to ask yourself in order to determine how to approach upgrading your intake system.

The next component is the intake pipe, which is effectively the super highway for air traveling from the air box to the throttle body. The intake pipe has several important components to note. First, the mass air-flow sensor (MAF) will look like a small box or “fin” with a group of wires plugged in to it. The MAF sensor reads a percentage of the air volume entering the intake as well as air temperature then communicates these readings to the engine control unit/module (ecu/ecm) in order to assist in maintaining proper fuel management. Specific to the ability of the MAF to properly function is the internal diameter of the intake pipe. Pipe diameter is often ignored when installing an aftermarket system, yet is critical given the MAF sensor is calibrated to measure a set percentage of incoming air volume based on the internal diameter of the pipe. If the aftermarket pipe was to have a larger internal diameter, instead of the MAF reading 10% of the air volume as calibrated, it may now only be reading 6%. The consequence is a leaner air/fuel mixture where the engine lacks sufficient fuel. If significant, a lean condition will inevitably cause damage to the engine. Another component of the factory intake pipe may look like a larger “box” attached along the side. This hollow box is called a Helmholtz Resonator. The Helmholtz is basically a muffler for the intake system, which significantly reduces intake noise. Although it is easy to assume the Helmholtz creates a restriction to airflow, the design places it on the outside of the intake pipe and therefore creates no impairment to the air traveling through the system. When installing an aftermarket intake, this component is excluded, becoming the primary reason intake noise is now more audible. It’s a common misconception that increased noise from an aftermarket intake is solely the result of increased airflow.

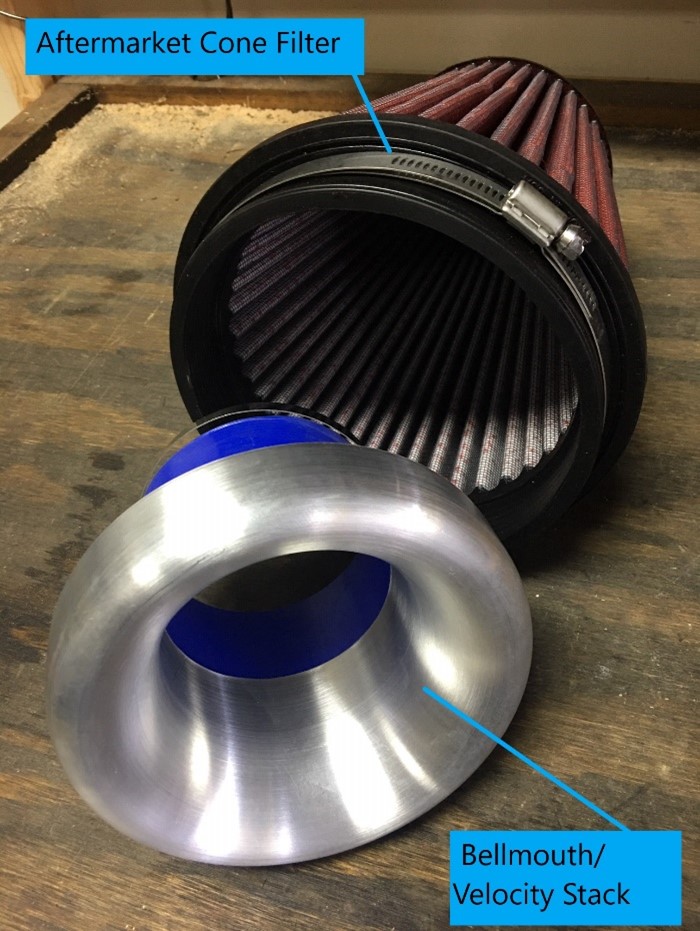

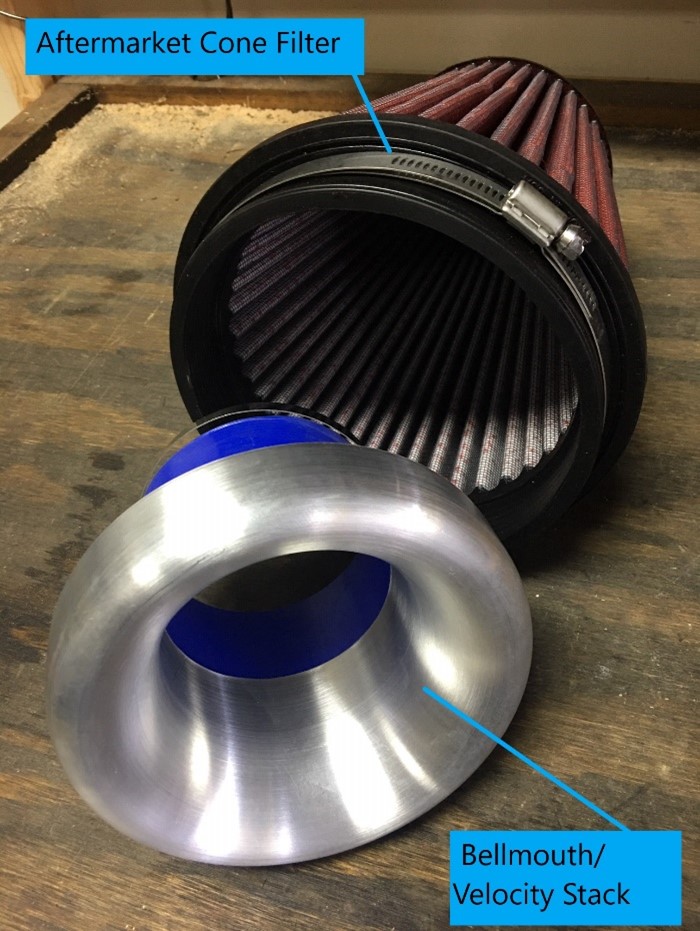

Depending on the factory intake design, it’s worth mentioning a couple other important engineering aspects to pay attention to. You may observe a honeycomb or cross-hatched screen at some point along the intake pipe, before and/or after the MAF, or immediately after the throttle body. These air straighteners are purposeful and necessary due to their ability to stabilize airflow. Air turbulence can be problematic because it acts as a type of restriction, causing decreased air volume further along the intake path or interfere with the MAF reading properly. Despite the straightener appearing to be an obstruction, it actually serves to increase volumetric efficiency by stabilizing the incoming air, improving intake air velocity, and inevitably aiding the air in forming vortexes (little tornadoes) further along the intake path. These vortexes are actually very organized and stable pockets of compacted air, a critical part of the airflow dynamics inside an intake. Second, inside the air box, you might observe a short section that is wide and turned outward at the opening, then narrows down to the same diameter as the intake pipe. This “bell” shaped opening is referred to as a velocity stack and aids the transition of air into the intake. Velocity stacks are like interstate on-ramps. Their purpose is to transition particles from a slow moving/high pressure side to the fast moving (high velocity)/low pressure intake side. Just like an on-ramp: the goal is to accelerate as you enter the flow of traffic on the interstate. Once on the interstate you have a greater volume of particles that are also traveling at a higher velocity. Another benefit of velocity stacks is that the transition of particles is smoother (less turbulent). As we have already discussed with air straighteners, reducing air turbulence is critical for maximizing airflow in order to get the most from your intake.

As we begin to consider installation of an aftermarket intake we need to take a look at the air filtration system. Inside the factory air box you will find a “drop-in” panel filter. The panel filter is designed to clean the air coming into the intake; removing dust, bugs, pollen, or other contaminants. Although they do a great job, factory filters tend to be restrictive and contribute to lower volumetric efficiency. Further consequences of a restrictive filter is that it takes more energy to pull air through. With the engine having to work harder drawing air in there is inherently a small loss of efficiency and power. Comparatively, performance filters offer a less restrictive material for significantly improved airflow and increased volumetric efficiency at the cost of filtration.

The most common filters you will see are the “oiled” or “dry-flow” filters. Aftermarket systems will include one or the other, with a select few giving you the option of which filter style you prefer. Oiled filters use an application of oil on the material to increase filtration by trapping contaminants. Dry flow filters refer to the absence of oil being used, leaving the material alone to trap contaminants. Both do an effective job at filtering, yet you will still see a lot of debate about which is best. The main argument centers on the use of oil and potential for it to damage your expensive MAF sensor. The reality is oiled filters don’t cause a problem when they are new. Problems result when owners remove the oiled filter, clean them, and then reapply fresh oil. Failure to allow the material to dry properly (Oil and water don’t mix!) and/or over saturation during re-oiling is to blame for oil being pulled from the filter material and coating the sensitive MAF; inevitably causing a failure. In the end, it’s up to you as the buyer to determine which best suits your needs. If you are comfortable cleaning and reapplying oil, then those types will work well for you. If you are not as comfortable, or simply wish to avoid the more extensive and costly cleaning process required of oiled filters, then the dry flow is likely the better choice. Additionally, given reduced filtration, use of an aftermarket filter should be given careful consideration if you live in an area with higher levels of dust, pollen, or other contaminants in the air.

If we were to simply install a less restrictive panel filter in the factory air box, we know it will reduce the amount of work the engine is doing to pull air in as well as improve the volumetric efficiency of the intake system. Now that the engine isn’t working as hard and the intake system is more efficient, a small amount of power is reclaimed, resulting in an estimated improvement of 3 to 5 horsepower and torque on most engines, specifically those with little to no other modifications. Certainly, factory engines that have larger displacement or are performance tuned from the factory may see more. Generally speaking, this is the maximum benefit that should be expected from installing a less restricting filter alone. This means simply upgrading from the factory drop-in air filter could achieve the same amount of power as installing a full aftermarket intake system. Depending on application, when a performance drop-in filter will typically cost less than $50 as compared to the majority of intake systems are over $150, that translates into a good amount savings for other mods that could add to your driving enjoyment. So under what circumstances does replacing the entire factory intake air-box and tube have any benefit?

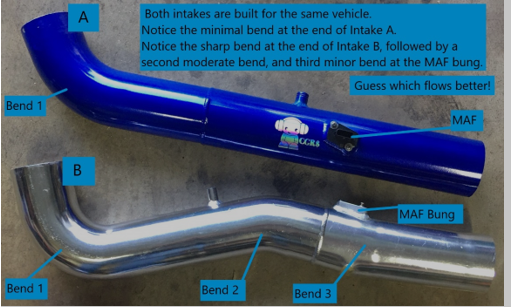

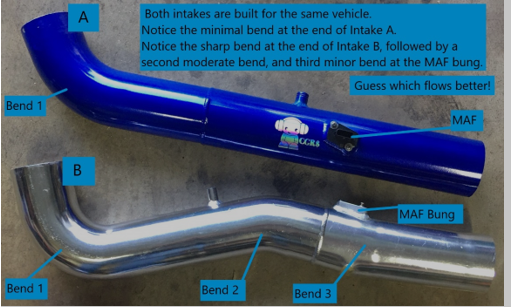

The factory intake itself can cause restrictions to airflow. These restrictions may be the result of build quality (material intruding into the intake path), pipe diameter, the number and severity of bends in the pipe, or poorly designed transitions between air passages. As the number and extent of restrictions increase, the more air volume and velocity will be reduced, resulting in lost efficiency. When looking at aftermarket options, systems that offer an improved build quality and a design that reduces the number and severity of bends is preferred. There is definite truth in the saying the best way to get from point A to point B is a straight line. So the more direct an intake path you can achieve, you can also expect increased air velocity and improved volume. Something else to consider when looking at aftermarket intakes is the construction material. You will notice they are most often made from either aluminum or plastic. Depending on your vehicle, the material could be a significant factor to consider. Aluminum will be more susceptible to absorbing heat from the engine bay, subsequently transferring some of that to the air flowing inside and increasing air intake temps. The pathway/location of the intake pipe will play a role in the extent heat affects the pipe, and should be considered when deciding which intake to buy. Keep in mind with certain applications, aluminum intakes will have little to no impact on intake air temps, so definitely don’t exclude aluminum as an option for your setup. This is an excellent example of how vehicle pages and forums can offer valuable information regarding different intake designs specific to your vehicle.

In regard to further stabilizing airflow for maximizing air velocity and volume there are a couple things we already know will work. You may have noticed that some aftermarket filters have a large opening where it is supposed to connect onto the intake. This opening is purposefully designed for a bell mouth/velocity stack. Velocity stacks are a fairly common component that are added to join intake pipes and aftermarket cone filters. As we already discussed, bell mouths help to smooth airflow as it transitions from the air filter into the intake pipe, further increasing air intake velocity as well as volume. While not all aftermarket intakes will have a velocity stack as part of the system, those that do are likely to outperform other intakes, specifically in the higher rpm range. For the truck community, the application of a velocity stack is less critical for low end power, but it will still function to smooth out airflow entering the system as well as provide a benefit to power in the upper rpm’s at no risk of losing power on the low end. A second way to stabilize airflow is to use an air straightener. While most aftermarket intakes fail to include these, likely due to added complexity and cost, they can be purchased individually and added into the system. Depending on the engine and other mods, you might expect to see 2hp from use of a bell mouth and/or air straightener. I think it’s important to emphasis, like all the other modifications we are discussing, bell mouths and air straighteners don’t “add” power, they reclaim power otherwise lost to inefficiencies inherent in system. By stabilizing airflow you can improve the MAF’s ability to monitor incoming air, increase air velocity as well as volume, and you allow the best conditions for vertices to form along the air path. This further enhances overall volumetric efficiency for the intake and provides engines the best opportunity to make the most power – limited only by restrictions elsewhere (ie. exhaust and tuning).

When considering intake options it’s necessary to discuss differences regarding intake length and the effect on engine performance. Although intake length should be viewed as the distance from the cylinder to the entrance of the intake system, any modification that increases or decreases the points between A and B applies to this topic. Simply, a shorter intake path will improve engine power in the higher rpm’s where a longer path will improve power in the low rpm’s. It’s worth noting, through the years more manufacturers have incorporated intake manifolds that are designed to offer the benefit of both. These variable intake air systems effectively shorten or lengthen the distance air travels before entering the combustion chamber. The result is a vehicle that benefits from both sides of the equation: allowing improved power down low when pulling out from a stop and once accelerated, shifting that power to the higher rpms where it is then most needed. The easiest way to alter intake length is to change the intake pipe itself. For truck owners that need low-end power for hauling, towing and climbing, keeping with a longer intake path is best. Conversely, lighter vehicles that benefit from power in higher rpm’s will benefit from a shorter intake path. While your factory manifold may use a variable intake, changing the intake pipe length will still have an effect on where in the rpm range engine power will exist. It’s worth emphasizing that typically you will not be gaining or losing power running a shorter or longer intake. You are simply moving that power up or down the rpm range of the engine. Once again we are back to the question about what you need from your vehicle given how you use it. Something to consider with shorter intake designs is the loss of a sealed air box which increases filter exposer to contaminants and allows the consumption of warmer air. Of course, if you want more power in the higher rpms, then it’s likely you will be traveling at a higher speed where increased airflow will drop under hood temperatures. At slower speeds, heat will further diminish engine power on the bottom end.

Regardless of the intake design you choose, pay close attention to filter placement and the potential for exposure to moisture. If the intake setup places the filter low on the vehicle or leaves the filter open it will be susceptible to submersion. If the filter is placed higher on the vehicle but remains exposed, it is still susceptible to water coming around the headlight and underneath the hood when raining or submersion if traveling through high water. The inherent design of true “cold air” intakes place the filter inside a boxed housing; reducing the ability for water contamination and submersion. Therefore, anyone looking for off-road adventures, choosing an intake that best protects the filter is ideal. It should go without saying, if water reaches your intake it is expected to also reach your engine, which would be catastrophic.

A critical component for off-road enthusiasts that builds on cold air intakes is the use of snorkels. Snorkels improve the intake’s ability to draw in air from the coolest source available. Not only is air pulled from outside the engine bay, it’s taken from an elevated position away from the heated asphalt/ground, and away from the vehicle’s body panels. Despite the notion snorkels are intended solely to keep moisture from entering the intake system during water crossings, they are also effective at providing the coolest air intake temps while also extending the intake path. As we have established at this point, these factors further benefit power in the lower rpm’s. However, there are limits – you can’t just keep extending the intake and it also continue to increase low end power indefinitely. Regretfully, there is a trade-off. Because we are adding bends to the intake path, there will be some degree of loss in volumetric efficiency. For this reason, the length associated with snorkels are not benefiting engine performance as much as the fact cooler air is being accessed. Given that snorkels can help drop intake temps several degrees, gains of 3 to 5 horsepower are reasonable, especially when compared to power achieved pulling air from warmer sources. Keeping in mind, under engine temps can get exceedingly high during off-road activities where little airflow and high engine rpms occur for extended periods of time.

Hopefully, this article has provided insight into the complexity of intakes and will aid in your search for the setup that best suits your needs. Once you have a clear picture of what your needs are, it definitely makes it easier to weed through the marketing behind generic descriptions and big claims manufacturers publish about their products. However, I cannot emphasize enough the importance of finding knowledgeable resources. Although many look to the social media groups for answers, these tend to be micro-responses, subsequently lacking the depth and comprehensive knowledge which can be found elsewhere. Above all, don’t hesitate to ask for additional resources or research on your own to further educate yourself. Without question, the guys at Alldogs Off-Road have the experience and knowledge to help get you the answers and products you need! Good luck and stay safe!

Special thanks to Jake Justice, Virginia Gregg, and Douglas Sands!